- Home

- Products

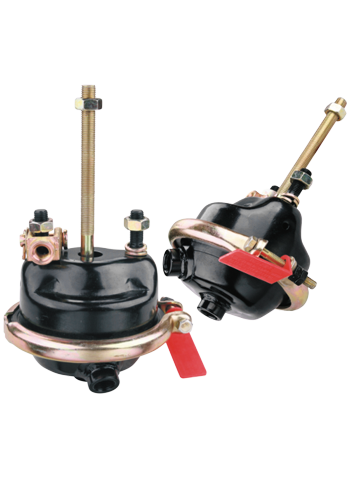

- Brake Chamber

- Manual Slack Adjuster

- Auto Slack Adjuster

- Air Suzie

- Palm Coupling

- Hydraulic Hose

- Swift Joint

- Quick Release Valve

- Unloader Valve

- Air Dryer

- Relay Valve

- Foot Brake Valve

- Circuit Protection Valve

- Hand Brake Valve

- Clutch Booster

- Levelling Valve

- Gear Box Valve

- ELC Valve

- Switch Part

- Cylinder

- Fuel Pump

- ABS Ecas

- Clutch Cylinder

- Tensioner

- Cabin Pump

- Brake Shoe Kit

- Tire Screw

- Union

- HUB Cover

- Cabin Lock

- “U” Lock

- Brake Chamber

- Manual Slack Adjuster

- Auto Slack Adjuster

- Air Suzie

- Palm Coupling

- Hydraulic Hose

- Swift Joint

- Quick Release Valve

- Unloader Valve

- Air Dryer

- Relay Valve

- Foot Brake Valve

- Circuit Protection Valve

- Hand Brake Valve

- Clutch Booster

- Levelling Valve

- Gear Box Valve

- ELC Valve

- Switch Part

- Cylinder

- Fuel Pump

- ABS Ecas

- Clutch Cylinder

- Tensioner

- Cabin Pump

- Brake Shoe Kit

- Tire Screw

- Union

- HUB Cover

- Cabin Lock

- “U” Lock

- About Us

- News

- Contact Us

ES

ES EN

EN RU

RU SA

SA